Laser Drilling of High-Density Micro Holes

Combined Motion Technologies for High Precision, High Aspect Ratio and Fast Drilling

When laser drilling the smallest high-density holes, many factors such as cone shape control as well as spot size and wavelength of the laser will have an impact on the result. In addition, fast and precise positioning of the workpiece, the laser head and the laser focus height is important. With the right combination of appropriate motion technologies and user-friendly control strategies to synchronize laser power, repetition rates and laser frequency with motion, it is possible to maintain hole accuracy and density over a wide range, thus increasing the throughput and quality of the laser drilling process.

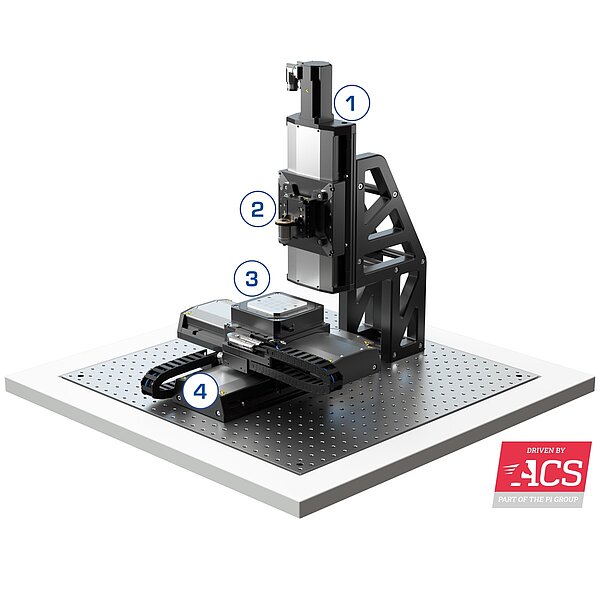

Z Axis – Reliable Laser Height Control

- High-precision ball screw linear stage with servo motor and holding brake for safe and reliable operation under high loads

- Absolute encoders to avoid collisions

- Robust industrial IP65 connectors for flexible cable exits

- Side seal and hard cover to protect from particles

>> L-417 High-Load Linear Stage

Z Axis – Dynamic Laser Focusing for Taper Control

- Voice coil direct-drive motor for friction-free operation and high scan frequencies

- Fast step-and-settle

- Integrated linear encoders for accurate position feedback

- Adjustable weight force compensation for safe operation

- Easy integration thanks to flexible mounting options

>> V-308 Voice Coil PIFOC® Focus Drive

XY Axis – Fine Positioning of the Workpiece

- Piezo-based XY scanner for highly-dynamic positioning with nanometer precision

- Parallel-kinematic design for equal dynamics in X- and Y-directions

- High guiding accuracy thanks to zero-play flexure guides

- Subnanometer resolution with long-term stability

- Fast ms settling times

- High tracking accuracy in the nanometer range

>> P-527 Multi-Axis Piezo Scanner

XY Axis – Workpiece Positioning Over Extended Travels

- Highly-dynamic ironless linear motors for fast and precise contouring

- Reference edge for easing alignment in the machine

- Connector for purge air, plus side seal, and hard cover, to protect against particles

- Absolute encoders avoid referencing and ensure safety during operation

>> V-417 High-Load Linear Stage

Flexible and Easy Automation Control

- Profile generation via EtherCAT® or triggering of predefined drilling profiles

- Intuitive browser-based software for system operation

- Laser pulse control via EtherCAT® or analog power output

>> Laser Control Interface - Servo control for fast step-and-settle and for disturbance rejection

>> ServoBoost™ - Option of adding fast piezo control for improved performance

>> Controllers and Drivers