|

Housing type

|

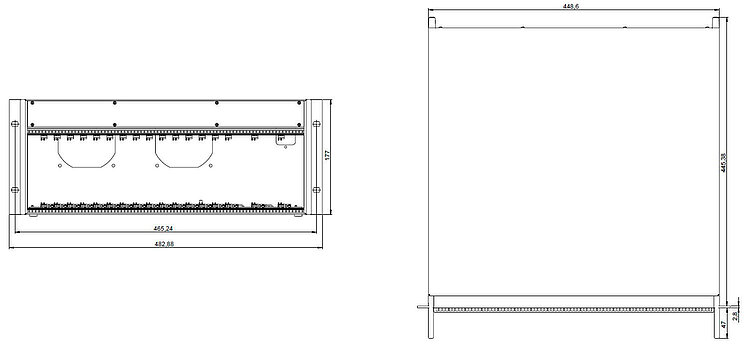

Rack insert 19" 4U

|

Rack insert 19" 4U

|

Rack insert 19" 4U

|

Rack insert 19" 4U

|

|

|

Drive type

|

PICMA®

|

PICMA®

|

PICMA®

|

PICMA®

|

|

|

Axes

|

3

|

3

|

6

|

6

|

|

|

Output channels

|

4

|

4

|

8

|

8

|

|

|

Input channels

|

3

|

3

|

6

|

6

|

|

|

Processor

|

PC-based

|

PC-based

|

PC-based

|

PC-based

|

|

|

Application-related functions

|

Makro ǀ Startup macro ǀ Data recorder

|

Makro ǀ Startup macro ǀ Data recorder ǀ Fast Alignment

|

Makro ǀ Startup macro ǀ Data recorder

|

Makro ǀ Startup macro ǀ Data recorder ǀ Fast Alignment

|

|

|

Drive functions

|

AutoZero

|

AutoZero

|

AutoZero

|

AutoZero

|

|

|

Protective functions

|

Deactivation of the voltage output in case of internal overheating ǀ Switch-off of the servo mode in case of an error ǀ Automatic motor stop

|

Deactivation of the voltage output in case of internal overheating ǀ Switch-off of the servo mode in case of an error ǀ Automatic motor stop

|

Deactivation of the voltage output in case of internal overheating ǀ Switch-off of the servo mode in case of an error ǀ Automatic motor stop

|

Deactivation of the voltage output in case of internal overheating ǀ Switch-off of the servo mode in case of an error ǀ Automatic motor stop

|

|

|

Configuration management

|

Import of parameter files ǀ Reading the ID chip ǀ Manual parameter input

|

Import of parameter files ǀ Reading the ID chip ǀ Manual parameter input

|

Import of parameter files ǀ Reading the ID chip ǀ Manual parameter input

|

Import of parameter files ǀ Reading the ID chip ǀ Manual parameter input

|

|

|

Supported ID chip

|

ID chip 2.0

|

ID chip 2.0

|

ID chip 2.0

|

ID chip 2.0

|

|

|

Motion and control

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Supported sensor signal

|

analog (cap.)

|

analog (cap.)

|

analog (cap.)

|

analog (cap.)

|

|

|

Control variables

|

Position

|

Position

|

Position

|

Position

|

|

|

Maximum control frequency (servo cycle)

|

50000 Hz

|

50000 Hz

|

20000 Hz

|

20000 Hz

|

|

|

Motion types

|

Point-to-point motion ǀ Point-to-point motion with profile generator ǀ Wave generator

|

Point-to-point motion ǀ Point-to-point motion with profile generator ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator

|

Point-to-point motion ǀ Point-to-point motion with profile generator ǀ Wave generator

|

Point-to-point motion ǀ Point-to-point motion with profile generator ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator

|

|

|

Motion coordination

|

Coordinated multi-axis motion

|

Coordinated multi-axis motion

|

Coordinated multi-axis motion

|

Coordinated multi-axis motion

|

|

|

Interfaces and operation

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Communication interfaces

|

TCP/IP ǀ USB

|

TCP/IP ǀ USB

|

TCP/IP ǀ USB

|

TCP/IP ǀ USB

|

|

|

On/off switch

|

Hardware switch on/off

|

Hardware switch on/off

|

Hardware switch on/off

|

Hardware switch on/off

|

|

|

Display and indicators

|

Error LED ǀ Power LED ǀ On Target LED ǀ Overtemp LED

|

Error LED ǀ Power LED ǀ On Target LED ǀ Overtemp LED

|

Error LED ǀ Power LED ǀ On Target LED ǀ Overtemp LED

|

Error LED ǀ Power LED ǀ On Target LED ǀ Overtemp LED

|

|

|

Command set

|

GCS 2.0

|

GCS 2.0

|

GCS 2.0

|

GCS 2.0

|

|

|

User software

|

PIMikroMove

|

PIMikroMove

|

PIMikroMove

|

PIMikroMove

|

|

|

Application programming interfaces

|

C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python

|

C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python

|

C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python

|

C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python

|

|

|

Linearization

|

DDL option (Dynamic Digital Linearization) ǀ 4th order polynomials

|

DDL option (Dynamic Digital Linearization) ǀ 4th order polynomials

|

DDL option (Dynamic Digital Linearization) ǀ 4th order polynomials

|

DDL option (Dynamic Digital Linearization) ǀ 4th order polynomials

|

|

|

Analog inputs

|

—

|

4

|

—

|

4

|

|

|

Analog input signal

|

—

|

±10.675 V differential, input impedance 150 kΩ, bandwidth maximum 25 kHz

|

—

|

±10.675 V differential, input impedance 150 kΩ, bandwidth maximum 25 kHz

|

|

|

Digital resolution of the analog input

|

—

|

18 bit

|

—

|

18 bit

|

|

|

Analog outputs

|

—

|

4

|

—

|

4

|

|

|

Analog output signal

|

—

|

±12.775 V, output current maximum 60 mA per output, bandwidth maximum 12 kHz

|

—

|

±12.775 V, output current maximum 60 mA per output, bandwidth maximum 12 kHz

|

|

|

Digital resolution of the analog output

|

—

|

16 bit

|

—

|

16 bit

|

|

|

Amplifier

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Resolution DAC/voltage resolution

|

20 bit

|

20 bit

|

20 bit

|

20 bit

|

|

|

Sensor

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Digital resolution for the sensor input

|

18 bit

|

18 bit

|

18 bit

|

18 bit

|

|

|

Sensor bandwidth

|

10 kHz

|

10 kHz

|

10 kHz

|

10 kHz

|

|

|

Electrical properties

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Output voltage

|

-30 to +135 V

|

-30 to +135 V

|

-30 to +135 V

|

-30 to +135 V

|

|

|

Short-circuit proof

|

Yes

|

Yes

|

Yes

|

Yes

|

|

|

Average output power per channel

|

8 W

|

8 W

|

8 W

|

8 W

|

|

|

Peak output power per channel

|

25 W

|

25 W

|

25 W

|

25 W

|

|

|

Peak output power per channel, time limit

|

5 ms

|

5 ms

|

5 ms

|

5 ms

|

|

|

Average output current per channel

|

150 mA

|

150 mA

|

150 mA

|

150 mA

|

|

|

Peak output current per channel

|

250 mA

|

250 mA

|

250 mA

|

250 mA

|

|

|

Peak output current per channel, time limit

|

5 ms

|

5 ms

|

5 ms

|

5 ms

|

|

|

Miscellaneous

|

E-713 PICMA® Controller, 3 axes

|

E-713 PICMA® Controller, 3 axes, analog I/O

|

E-713 PICMA® Controller, 6 axes

|

E-713 PICMA® Controller, 6 axes, analog I/O

|

|

|

Motor/actuator connector

|

D-sub 25W3

|

D-sub 25W3

|

D-sub 25W3

|

D-sub 25W3

|

|

|

Sensor connector

|

D-sub 25W3

|

D-sub 25W3

|

D-sub 25W3

|

D-sub 25W3

|

|

|

Connector analog input

|

—

|

LEMO EPG.00.302.NLN

|

—

|

LEMO EPG.00.302.NLN

|

|

|

Connector analog output

|

—

|

LEMO EPG.00.302.NLN

|

—

|

LEMO EPG.00.302.NLN

|

|

|

Connector TCP/IP

|

RJ45 socket, 8P8C

|

RJ45 socket, 8P8C

|

RJ45 socket, 8P8C

|

RJ45 socket, 8P8C

|

|

|

Connector USB

|

USB socket type B

|

USB socket type B

|

USB socket type B

|

USB socket type B

|

|

|

Connector for supply voltage

|

IEC 60320 type C14

|

IEC 60320 type C14

|

IEC 60320 type C14

|

IEC 60320 type C14

|

|

|

Power connection

|

100 to 240 V AC ǀ 50 to 60 Hz

|

100 to 240 V AC ǀ 50 to 60 Hz

|

100 to 240 V AC ǀ 50 to 60 Hz

|

100 to 240 V AC ǀ 50 to 60 Hz

|

|

|

Power entry fuse

|

1 x T6.3AH, 250 V

|

1 x T6.3AH, 250 V

|

1 x T6.3AH, 250 V

|

1 x T6.3AH, 250 V

|

|

|

Maximum power consumption

|

330 W

|

330 W

|

330 W

|

330 W

|

|

|

Operating temperature range

|

5 to 40 °C

|

5 to 40 °C

|

5 to 40 °C

|

5 to 40 °C

|

|

|

Overall mass

|

7892 g

|

8054 g

|

8584 g

|

8746 g

|

|