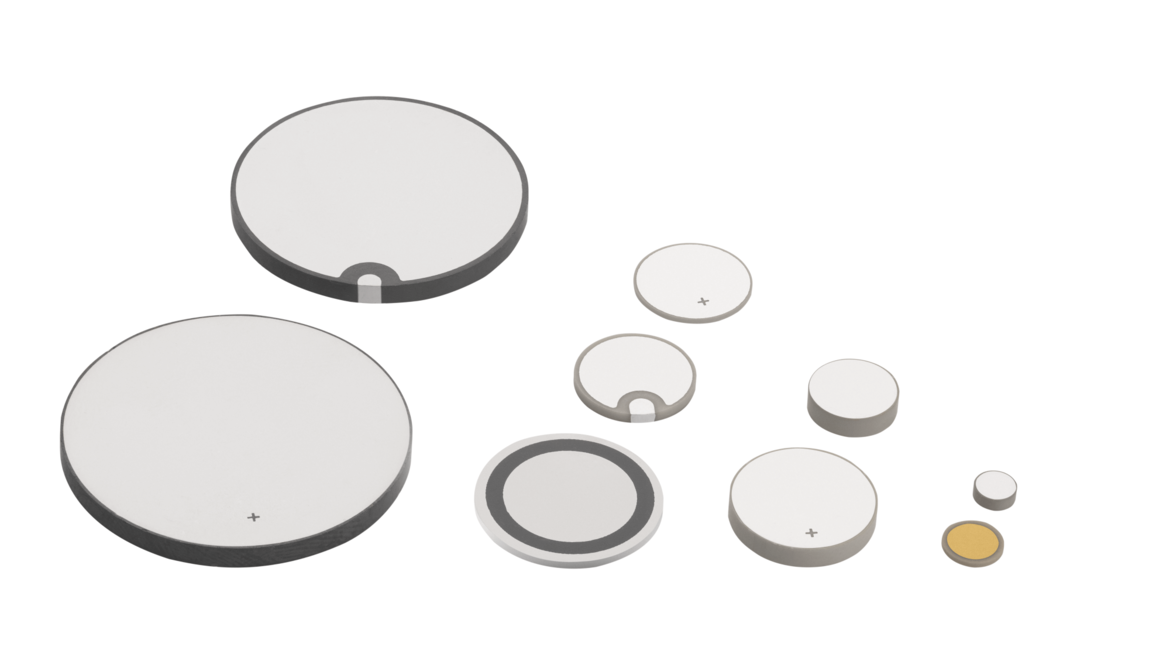

圧電素子は、特に超音波技術で幅広く利用されるほか、センサーやアクチュエーターでも活用されています。 適切なピエゾセラミック材料の選択は、各用途の具体的な要件によります。 ピエゾディスクは、さまざまな形状・サイズで製造可能です。

工業用超音波技術では、圧電部品が流量センサーや非破壊材料検査などに利用されます。 また、医療技術では、輸液ライン内の生命に関わる気泡を正確に検出するために利用されます。

圧電部品を精密に加工することで、用途に応じた個別の特性が実現可能です。 ディスクを組み合わせることで、トランスデューサー素子などのより複雑な機能ユニットを作ることもできます。

仕様

PI Ceramicは、30年以上のピエゾセラミックの開発・製造の実績を活かし、材料選定から用途に応じたカスタマイズソリューションの開発まで、一貫したサービスを提供しています。

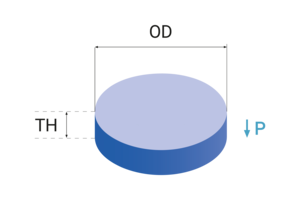

ピエゾディスクの寸法は、規定の範囲内でお客様のご要望に合わせて指定できます。 実現可能性の検証をご希望の方は、ディスクの仕様やご希望の寸法をお知らせください。

| 外径 OD(単位:mm) | 1 ~ 80 |

| 厚さ TH(単位:mm) | 0.15 ~ 30 |

| 電極 | 厚層(Ag)、薄層(Ag、Au、CuNi、Cu、NiV)、無電解ニッケル |

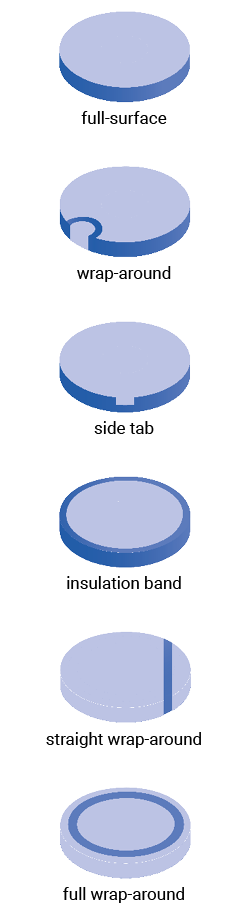

| 電極設計 | 様々な設計をお選びいただけます:全面、ラップアラウンド、サイドタブ、絶縁バンド、ストレートラップアラウンド、フルラップアラウンド(右欄参照) |

| 終端 | はんだ付け、ワイヤボンディング、フレキシブル回路基板など、さまざまな終端方法に対応しています。 |

| 分極方向 | ピエゾ部品の設計に応じて、軸方向と半径方向への変位を実現できます。 詳細については、>> 動作モードをご覧ください。 |

| 材料 | 強誘電体ソフトおよびハードPTZ材料、鉛フリー代替材料もご用意しています。 材料の概要については、>> こちらをご覧ください。 関連するデータシートは、>> こちらから入手可能です。 |

| その他の機能 | より高度な改良に加えて、以下のようなさまざまな技術も利用可能です。

|

| 用途 | ピエゾセラミックリングは、さまざまなセンサーやアクチュエーターの用途に適しています。 活用事例は、>> こちらをご覧ください。 |

動作モード

ピエゾセラミックディスクをセンサーとして使用する場合、直接圧電効果の原理に従います。 圧力や超音波などの機械荷重がセラミックに加わると、ピエゾ部品は電気信号を生成します。

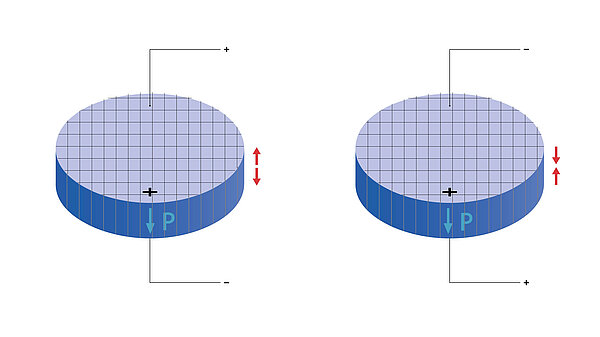

ピエゾディスクをアクチュエーターとして使用する場合、電圧をかけることで機械的変位が生成されます。 この変位は直流電流下では静的変形として、交流電流下では超音波範囲などの振動として生じます。 ピエゾ部品の設計に応じて、動作は縦方向または半径方向のどちらでも発生させることが可能です。 変位振幅は、ピエゾディスクのサイズと印加電圧の両方によって決まります。

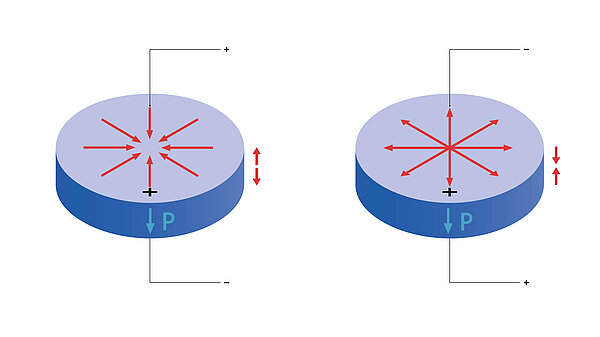

上面が正の分極方向があり、下面が負の分極方向があるディスクの場合、変位方向は以下のようになります。

軸方向の変位(d33効果)が発生すると、半径方向にも小さな変形(d31効果)が必ず発生します。

軸方向振動モードで特定の周波数に到達するには、ディスクの厚さを変更する必要があります。 一方、半径方向の周波数に到達するには、ディスクの直径を調整する必要があります。 いずれの場合も、 ディスクが大きいほど、周波数は低くなります。