高精度の産業用途向けヘキサポッド、ブラシレスDCモーター、耐荷重:10 kg、最大速度:20 mm/s、位置測定アブソリュートエンコーダ。 接続ケーブルは同梱されていませんので、別途ご注文ください。

H-815 高精度が求められる24時間365日稼働の産業用途向けヘキサポッド

Compact, Robust, and Precise

- Integrated brakes for safe handling and high process reliability

- Fast system start thanks to position data without referencing due to absolute encoders

- Robust design for long service life with high duty cycles

- High throughput thanks to long-term reliability

- Compact design for easy integration

- Easy cable management with pluggable cables

- High precision thanks to exceptional design and high-quality components

高荷重と24時間365日稼働に対応するスチュワートプラットフォーム

H-815は、優れた信頼性、高速性、正確な動作を特徴としており、シリコンフォトニクス、半導体製造、光学、計測などの用途に適しています。 精度、柔軟性、耐久性を兼ね備えているため、今日の高精度なアライメント作業に最適なツールです。 H-815産業用ヘキサポッドは、産業環境で24時間365日稼働するように設計された、コンパクトで堅牢なパラレルキネマティックモーションシステムです。

コンパクトな設置スペースで優れた堅牢性を実現

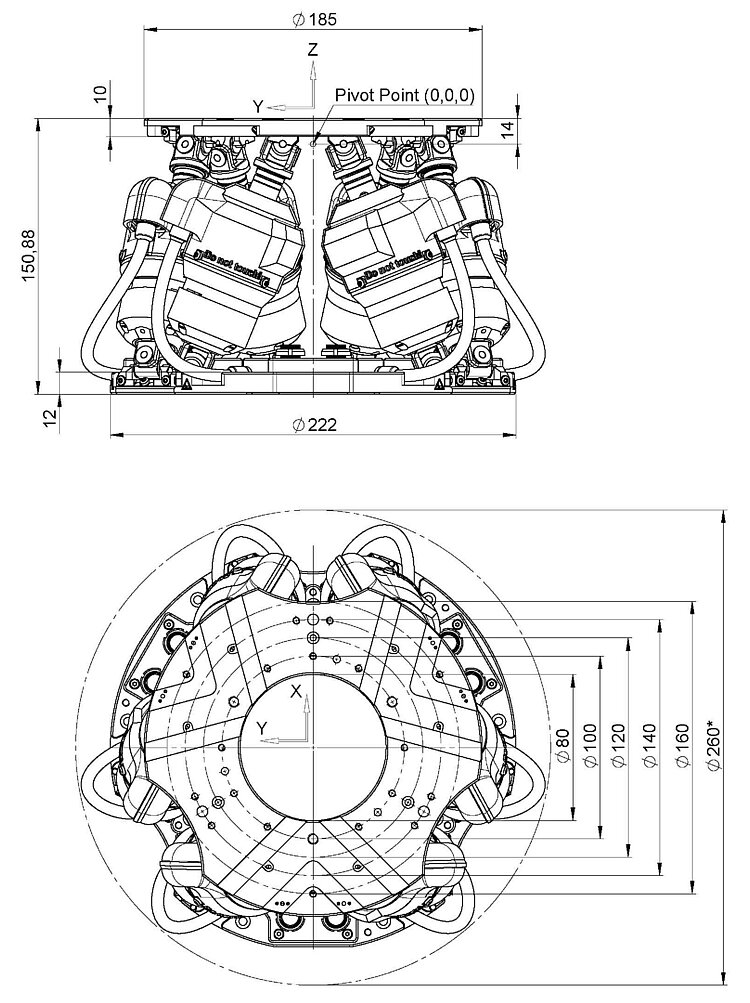

パラレルキネマティック配置により、H-815は非常にコンパクトな設計ながらも6軸の動作を実行できます。 薄型設計(高さ155 mm、ベースプレート直径222 mm)と最大10 kgの耐荷重・負荷容量により、このヘキサポッドは既存の生産ラインにシームレスにインテグレーション可能。さまざまな方向で信頼性の高い位置決めを実行し、一貫したパフォーマンスを発揮します。 産業用ヘキサポッドは、最大速度20 mm/s、最小インクリメンタルモーション0.05 µm、再現性±0.05 µmという高精度を実現します。 最大トラベルレンジは直線軸で±20 mm、回転軸で±16°です。 H-815はブレーキを内蔵しているため、コンパクトな設置スペースにおいても最大限の安全性と堅牢性を確保できます。 アブソリュートエンコーダにより、リファレンス動作なしですぐに稼働でき、優れた位置決め精度により作業効率とプロセスの信頼性が向上します。

応用分野

H-815ヘキサポッドは、フォトニクスにおける要求の厳しいアライメントプロセスに対応する、高精度の多軸モーションおよび位置決めシステムです。 優れた精度と再現性を備えており、レンズやその他の光学部品などの極めて小さな部品のアライメントに最適です。 6自由度の複雑な位置決め作業を、迅速かつ正確に再現性のある方法で実行します。 この産業用ヘキサポッドは、堅牢な設計により、卓越した耐久性と信頼性を実現します。 H-815は、要求の厳しい環境下における、産業オートメーションおよび組立プロセスでの常時使用を想定して設計されており、複雑な製造・計測プロセスの生産性を向上させます。

用途:

- レンズの精密アライメントおよび取り付け

- 光学部品およびアセンブリのアライメント

- フォトニクスおよび光学アセンブリ

- 高精度部品のマイクロアセンブリ

- 産業用アセンブリプロセス

- レーザー材料加工における精密制御

- 24時間365日稼働のオートメーション用途

仕様

仕様

| Motion | H-815.D6A3 | Tolerance |

|---|---|---|

| Active axes | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | |

| Travel range in X | ± 20 mm | |

| Travel range in Y | ± 20 mm | |

| Travel range in Z | ± 10 mm | |

| Rotation range in θX | ± 9 ° | |

| Rotation range in θY | ± 9 ° | |

| Rotation range in θZ | ± 16 ° | |

| Maximum velocity in X | 20 mm/s | |

| Recommended velocity in X | 15 mm/s | |

| Maximum velocity in Y | 20 mm/s | |

| Recommended velocity in Y | 15 mm/s | |

| Maximum velocity in Z | 20 mm/s | |

| Recommended velocity in Z | 15 mm/s | |

| Maximum angular velocity in θX | 340 mrad/s | |

| Recommended angular velocity in θX | 170 mrad/s | |

| Maximum angular velocity in θY | 340 mrad/s | |

| Recommended angular velocity in θY | 170 mrad/s | |

| Maximum angular velocity in θZ | 680 mrad/s | |

| Recommended angular velocity in θZ | 340 mrad/s | |

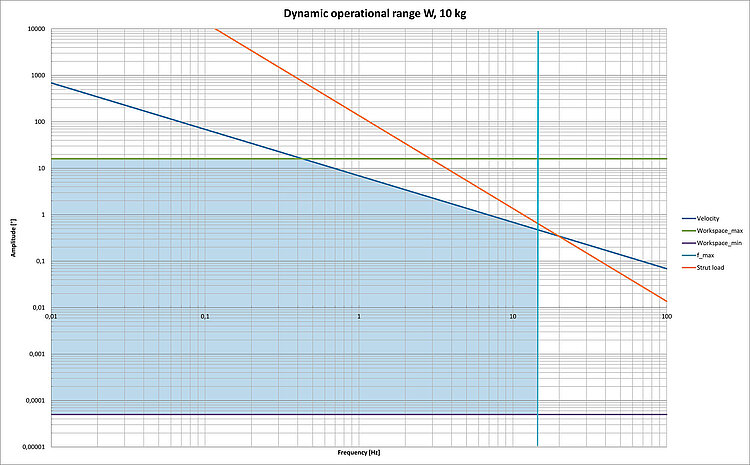

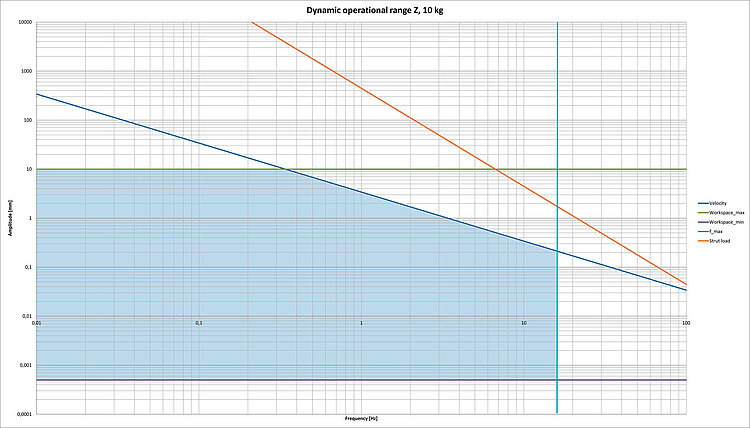

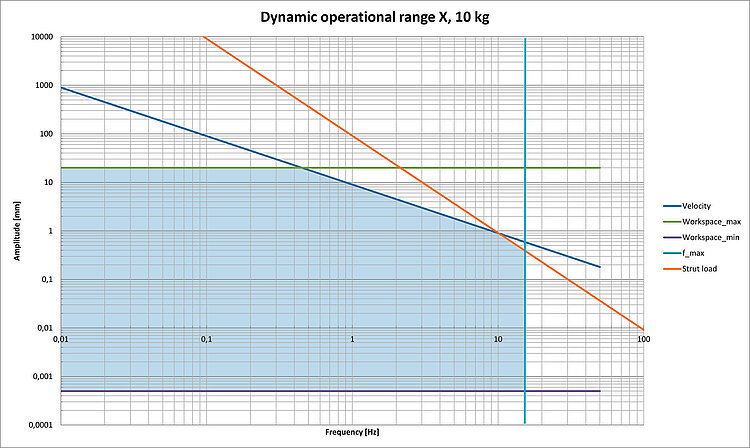

| Amplitude-frequency product in X | 9 mm·Hz | |

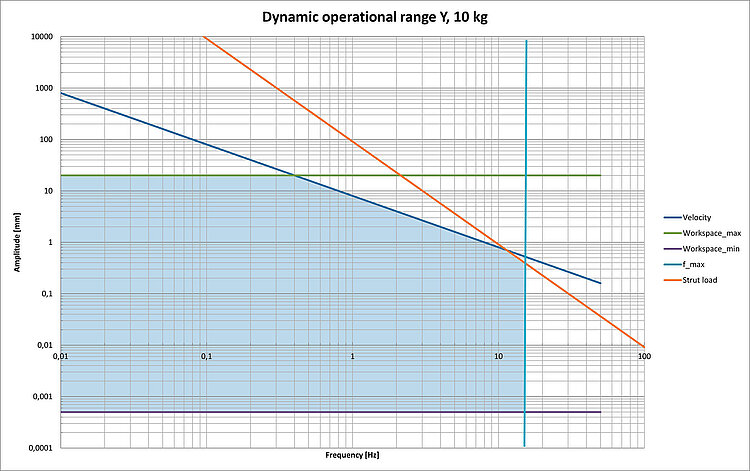

| Amplitude-frequency product in Y | 8 mm·Hz | |

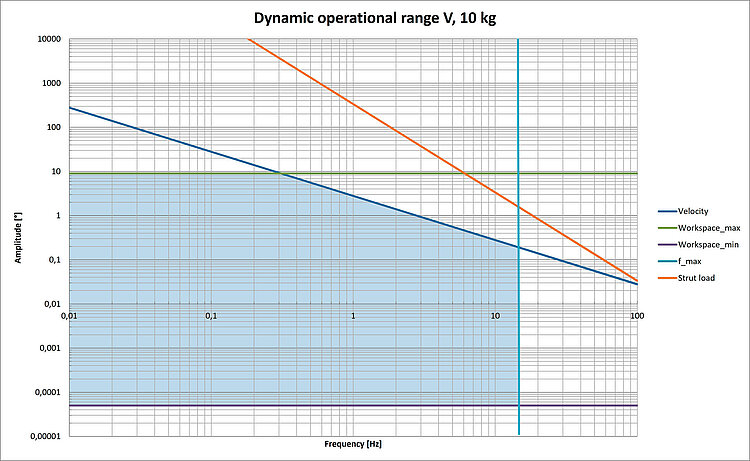

| Amplitude-frequency product in Z | 3.4 mm·Hz | |

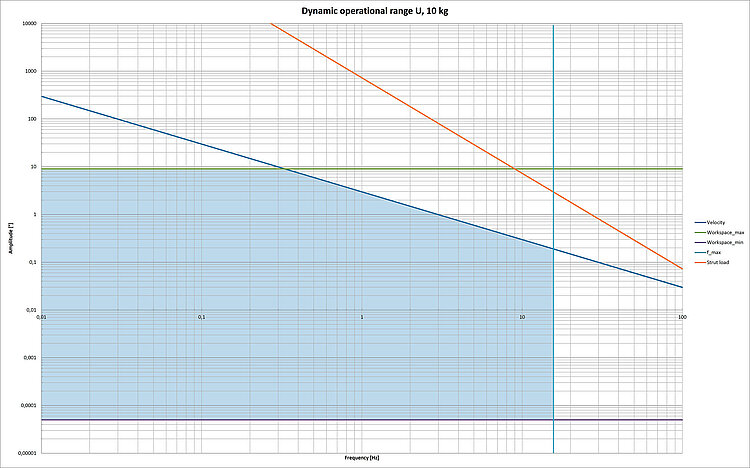

| Amplitude-frequency product in θX | 3 °·Hz | |

| Amplitude-frequency product in θY | 3 °·Hz | |

| Amplitude-frequency product in θZ | 6.9 °·Hz | |

| Amplitude-frequency² product in X | 91.2 mm·Hz² | |

| Amplitude-frequency² product in Y | 91.2 mm·Hz² | |

| Amplitude-frequency² product in Z | 445.8 mm·Hz² | |

| Amplitude-frequency² product in θX | 725.6 °·Hz² | |

| Amplitude-frequency² product in θY | 335 °·Hz² | |

| Amplitude-frequency² product in θZ | 136.4 °·Hz² | |

| Amplitude error | 5 % | max. |

| Maximum frequency | 30 Hz | |

| Positioning | H-815.D6A3 | Tolerance |

| Minimum incremental motion in X | 0.08 µm | typ. |

| Minimum incremental motion in Y | 0.08 µm | typ. |

| Minimum incremental motion in Z | 0.05 µm | typ. |

| Minimum incremental motion in θX | 1 µrad | typ. |

| Minimum incremental motion in θY | 1 µrad | typ. |

| Minimum incremental motion in θZ | 0.7 µrad | typ. |

| Unidirectional repeatability in X | ± 0.09 µm | typ. |

| Unidirectional repeatability in Y | ± 0.09 µm | typ. |

| Unidirectional repeatability in Z | ± 0.05 µm | typ. |

| Unidirectional repeatability in θX | ± 1 µrad | typ. |

| Unidirectional repeatability in θY | ± 1 µrad | typ. |

| Unidirectional repeatability in θZ | ± 0.7 µrad | typ. |

| Backlash in X | 2 µm | typ. |

| Backlash in Y | 2 µm | typ. |

| Backlash in Z | 0.1 µm | typ. |

| Backlash in θX | 1.6 µrad | typ. |

| Backlash in θY | 1.6 µrad | typ. |

| Backlash in θZ | 26.1 µrad | typ. |

| Integrated sensor | Absolute rotary encoder, multi-turn | |

| Drive properties | H-815.D6A3 | Tolerance |

| Drive type | Brushless DC motor | |

| Nominal voltage | 24 V | |

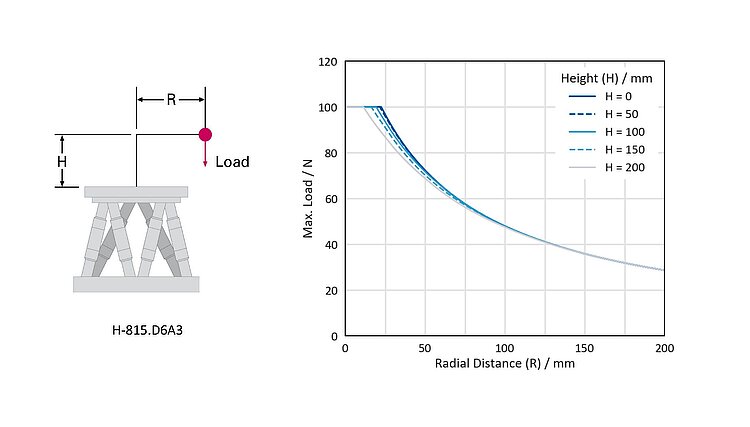

| Mechanical properties | H-815.D6A3 | Tolerance |

| Stiffness in X | 0.7 N/µm | |

| Stiffness in Y | 0.7 N/µm | |

| Stiffness in Z | 8 N/µm | |

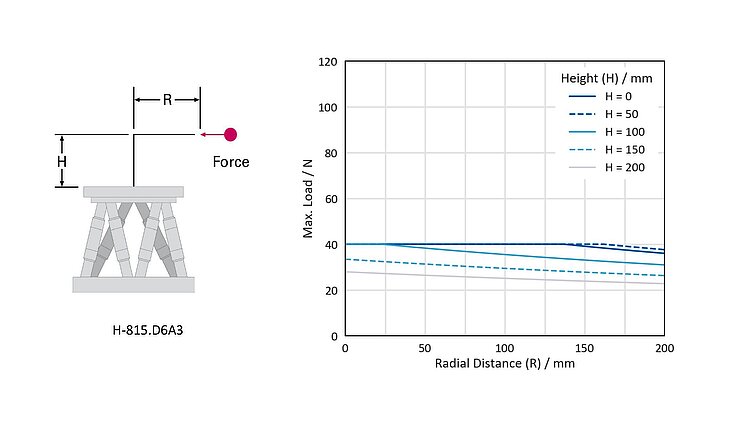

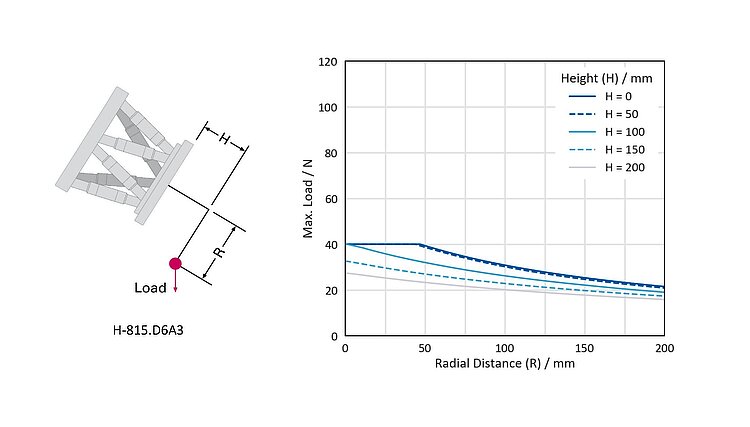

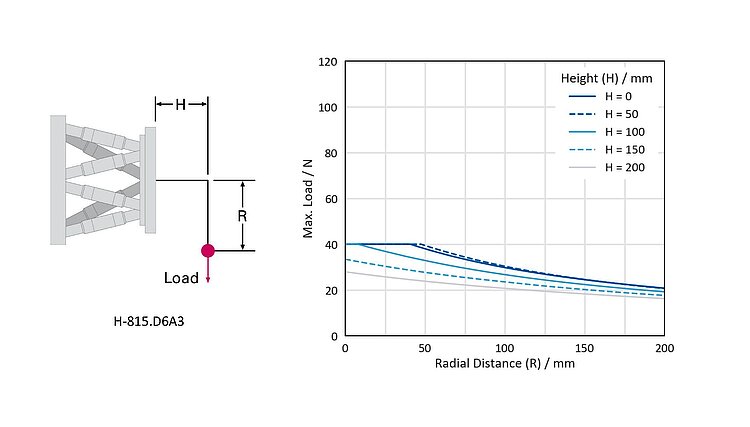

| Maximum load capacity, base plate horizontal | 10 kg | |

| Maximum load capacity, base plate in any orientation | 4 kg | |

| Maximum holding force, base plate horizontal | 100 N | |

| Maximum holding force, base plate in any orientation | 40 N | |

| Overall mass | 5.5 kg | |

| Material | アルミニウム、ステンレススチール | |

| Height | 155 mm | |

| Base plate diameter | 222 mm | |

| Miscellaneous | H-815.D6A3 | Tolerance |

| Operating temperature range | 0 to 50 °C | |

| Drive connector | 6 × Circular push-pull connector 16-pole (f) | |

| Recommended controllers/drivers | C-887.4xx1 |

ダウンロード

データシート

ドキュメント

User Manual MS260

Hexapod for Industrial 24/7 Applications with Highest Precision Requirements

Technical Note H815T0004

Technical note for unpacking the hexapod

Short Instructions MS263EK

Hexapod Systems: Hexapod H-815 with C-887.3x/.4x Controller with Integrated Drivers for BLDC Motors

3D モデル

H-815.D6A3 3D Model

H-815.D6A3 3D Model