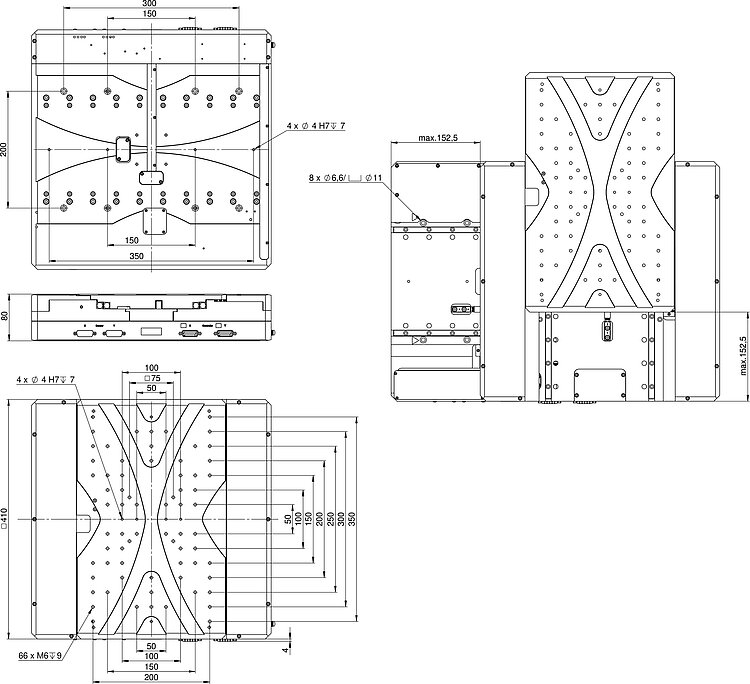

Precision XY stage; 2-phase stepper motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw

L-741 Precision XY Stage

High Run-Out Accuracy and Stability, 305 × 305 mm Travel Range

- Travel range 305 mm × 305 mm (12'')

- Unidirectional repeatability to 0.05 µm

- Velocity to 90 mm/s

- 2-phase stepper motor or DC motors

- Incremental linear encoder with 1 nm resolution

- Rotary encoder with 20000 impulses/revolution

Highly accurate position measuring with incremental linear encoder

Noncontact optical linear encoders measure the position directly at the platform with the greatest accuracy. Nonlinearity, mechanical play or elastic deformation have no influence on the measurement. Optical limit and reference switches. More travel ranges on request.

Crossed roller guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guide accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

Drive types

- 2-phase stepper motor for high torque even at low velocities and higher resolution

- DC motor for high velocity constancy, low vibration, and high velocities

Application fields

Medical industry. Laser cutting. Biotechnology. Measuring technology. Laser inscription.

Specifications

Specifications

| Motion | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

|---|---|---|---|---|---|---|---|

| Active axes | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | X ǀ Y | |

| Travel range in X | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | |

| Travel range in Y | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | 305 mm | |

| Maximum velocity in X, unloaded | 45 mm/s | 45 mm/s | 45 mm/s | 50 mm/s | 50 mm/s | 90 mm/s | |

| Maximum velocity in Y, unloaded | 45 mm/s | 45 mm/s | 45 mm/s | 50 mm/s | 50 mm/s | 90 mm/s | |

| Orthogonality | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | ± 96 µrad | typ. |

| Straightness error E_YX (straightness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | typ. |

| Straightness error E_ZX (flatness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 4 µm | typ. |

| Angular error E_AY (pitch) | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | typ. |

| Angular error E_BX (pitch) | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | ± 60 µrad | typ. |

| Angular error E_CX (yaw) | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | typ. |

| Angular error E_CY (yaw) | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | ± 40 µrad | typ. |

| Positioning | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Minimum incremental motion in X | 1 µm | 0.05 µm | 0.05 µm | 0.1 µm | 0.5 µm | 0.8 µm | typ. |

| Minimum incremental motion in Y | 1 µm | 0.05 µm | 0.05 µm | 0.1 µm | 0.5 µm | 0.8 µm | typ. |

| Unidirectional repeatability in X | ± 0.05 µm | ± 0.025 µm | ± 0.025 µm | ± 0.05 µm | ± 0.25 µm | ± 0.4 µm | typ. |

| Unidirectional repeatability in Y | ± 0.05 µm | ± 0.025 µm | ± 0.025 µm | ± 0.05 µm | ± 0.25 µm | ± 0.4 µm | typ. |

| Bidirectional repeatability in X | 5 µm | 1 µm | 1 µm | 1 µm | 1 µm | 5 µm | typ. |

| Bidirectional repeatability in Y | 5 µm | 1 µm | 1 µm | 1 µm | 1 µm | 5 µm | typ. |

| Reference switch | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | |

| Reference switch repeatability | 1 µm | 1 µm | 1 µm | 1 µm | 1 µm | 1 µm | |

| Limit switches | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | |

| Integrated sensor | — | Incremental linear encoder | Incremental linear encoder | Incremental linear encoder | Incremental linear encoder | Incremental rotary encoder | |

| Sensor signal | — | Sin/cos, 1 V peak-to-peak | A/B quadrature, RS-422 | Sin/cos, 1 V peak-to-peak | A/B quadrature, RS-422 | A/B quadrature, RS-422 | |

| Sensor signal period | — | 20 µm | — | 20 µm | — | — | |

| Sensor resolution | — | 1 nm | 10 nm | 1 nm | 10 nm | — | |

| Sensor resolution | — | — | — | — | — | 20000 Cts./rev. | |

| Drive properties | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Drive type | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | DC motor | DC motor | DC motor | |

| Operating voltage | 24 V | 24 V | 24 V | 24 V | 24 V | 24 V | |

| Nominal current, RMS | 1.2 A | 1.2 A | 1.2 A | 3.9 A | 3.9 A | 3.9 A | typ. |

| Motor resolution | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | — | — | — | |

| Drive force in X | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | typ. |

| Drive force in Y | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | typ. |

| Resistance phase-phase | 3.4 Ω | 3.4 Ω | 3.4 Ω | 0.62 Ω | 0.62 Ω | 0.62 Ω | typ. |

| Mechanical properties | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Permissible push force in Z | 200 N | 200 N | 200 N | 200 N | 200 N | 200 N | max. |

| Permissible torque in θX | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Permissible torque in θY | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Permissible torque in θZ | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | 125 N·m | max. |

| Moved mass in X, unloaded | 19900 g | 19900 g | 19900 g | 20200 g | 20200 g | 20200 g | |

| Moved mass in Y, unloaded | 6100 g | 6100 g | 6100 g | 6100 g | 6100 g | 6100 g | |

| Drive screw type | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | |

| Drive screw pitch | 2 mm | 2 mm | 2 mm | 2 mm | 2 mm | 2 mm | |

| Guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | |

| Overall mass | 27500 g | 27500 g | 27500 g | 28000 g | 28000 g | 28000 g | |

| Material | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | Black anodized aluminum | |

| Miscellaneous | L-741.131100 | L-741.131111 | L-741.131112 | L-741.133111 | L-741.133112 | L-741.133132 | Tolerance |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Connector | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | 2 × HD D-sub 26 (m) | |

| Sensor connector | — | 2 × D-sub 15 (f) | — | 2 × D-sub 15 (f) | — | — | |

| Recommended controllers/drivers | G-901.R319 G-902.R2E001 C-663.12, C-885 with C-663.12C885 ACS modular controller | G-901.R319 G-902.R2E001 ACS modular controller | G-901.R319 G-902.R2E001 C-663.12, C-885 with C-663.12C885 ACS modular controller | G-901.R319 G-902.R2E001 ACS modular controller | G-901.R319 G-902.R2E001 C-863.12, C-885 with C-863.20C885 ACS modular controller | G-901.R319 G-902.R2E001 C-863.12, C-885 with C-863.20C885 ACS modular controller |

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

データシート

ドキュメント

User Manual MP184

L-741 / V-741 Precision XY Stage

3D モデル

L-741 3-D model

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Precision XY stage; 2-phase stepper motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw; incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak

Precision XY stage; 2-phase stepper motor; 305 mm x 305 mm travel range (X × Y); 200 N load capacity; 45 mm/s × 45 mm/s maximum velocity; ball screw; incremental linear encoder, 10 nm sensor resolution, A/B quadrature, RS-422

Precision XY stage; DC motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 50 mm/s × 50 mm/s maximum velocity; ball screw; incremental linear encoder, 20 µm sensor signal period, sin/cos, 1 V peak-peak

Precision XY stage; DC motor; 305 mm x 305 mm travel range (X × Y); 200 N load capacity; 50 mm/s × 50 mm/s maximum velocity; ball screw; incremental linear encoder, 10 nm sensor resolution, A/B quadrature, RS-422

Precision XY stage; DC motor; 305 mm × 305 mm travel range (X × Y); 200 N load capacity; 90 mm/s × 90 mm/s maximum velocity; ball screw; incremental rotary encoder, 20000 counts/rev sensor resolution, A/B quadrature, RS-422

見積取得方法

お問い合わせ

担当者よりお問合せにつきまして、すぐにご連絡をさせて頂きます。

テクノロジー

従来のガイドシステム

数ミリメートルから1メートルまでのストロークを持つポジショナーは、通常、ボールベアリングなど、従来からある機械的ガイドコンポーネントを用います。

インクリメンタルセンサ

PI社では、約1mmから始まる長いトラベルレンジを測定するインクリメンタル測定システムを採用しています。これらのセンサは、ほとんどの場合光学センサですが、ピコメートルレンジまでの位置分解能を実現します。

多軸位置決めシステム

ヘキサポッドプラットフォームは、搭載物の6軸方向、つまり3つの直動軸と3つの回転軸に沿った高精度位置決め、および搭載物の位置調整のために使用されます。

回転電動モータ

DCモータやステッピングモータなどの回転電動モータは、ネジまたはウォーム駆動と連結して使用されます。

応用事例

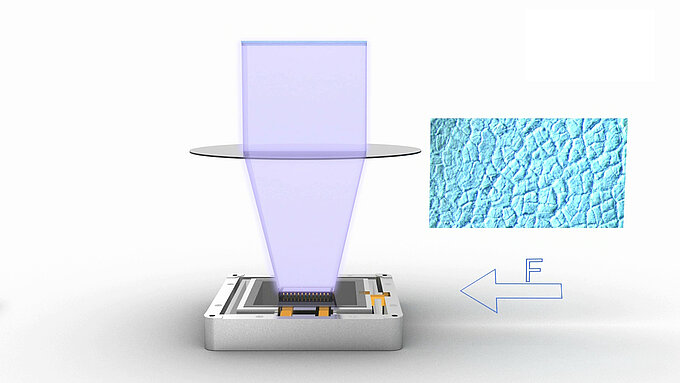

ゲノムシーケンス

Be it in medicine, forensics, or genetics - the genome is the key to new insights for numerous questions. The method known as sequencing-by-synthesis, which used to decipher the genome, has become faster and more precise since it was first developed — the cost has decreased, respectively. The positioning techniques employed in the microscope systems used for this purpose have also contributed to...

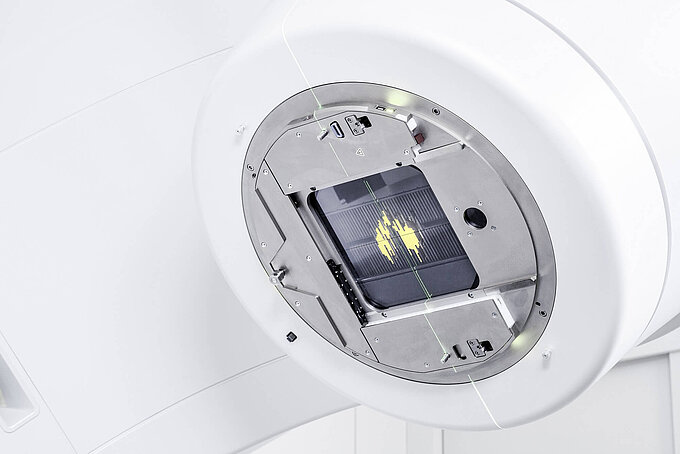

ビデオ内視鏡

現代の医療技術は、患者にできるだけ不快感を与えない治療法の開発に力を入れています。低侵襲手術を可能にする内視鏡は、例えば、腹腔鏡手術において大きく貢献しています。特に医療行為においては、最大限の成功を収めるために、焦点を絞った詳細な画像情報が最優先で求められます。

柔軟なダイヤフラムポジショニング

放射線治療では、健康な組織を放射線からの保護するために個別のリーフが調整されます。

画像安定化

ピエゾベースの高速スキャナーは、画像安定化およびマイクロスキャニングのためにビデオ周波数レンジに見合った速度で動作します。

ピペット

ピエゾモータは、デバイスとサンプルが狭いピペットに最適で、ピペットを垂直方向に動かすことができます。

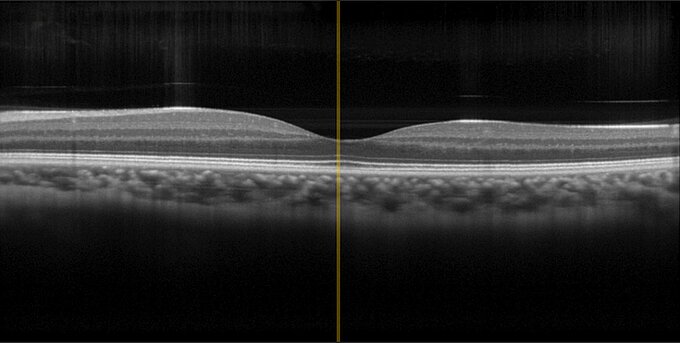

オプティカルコヒーレンストモグラフィー

ピエゾアクチュエータとドライブ (PILine® OEMモータ) は、オプティカルコヒーレンストモグラフィー (OCT) に必要な高い精度と位置の安定性を保証します。

MRI

ピエゾドライブは強力な磁場からの影響を受けないため、磁気共鳴治療に最適です。

屈折矯正手術

屈折矯正手術では、レーザの高精度なポジショニングとモーションコントロールが優れた結果を出す決め手となります。ピエゾによるステージやチップ/チルトミラーシステムは、求められる精度を提供し、ダイナミックかつ高速であるため、処理時間の短縮にも役立ちます。