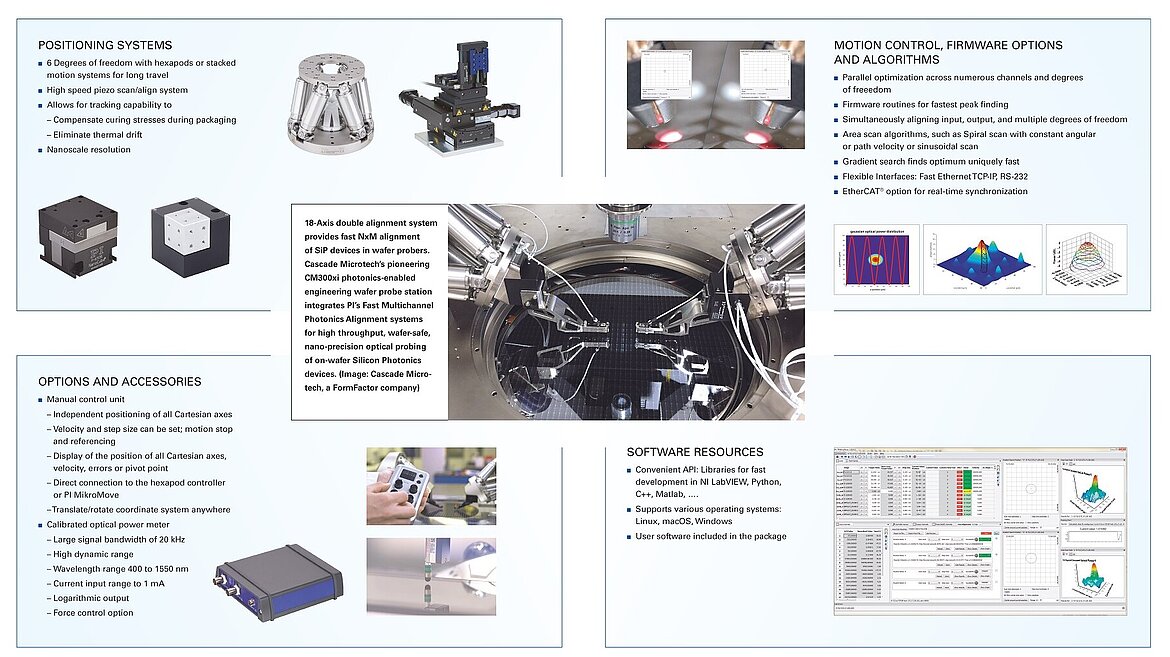

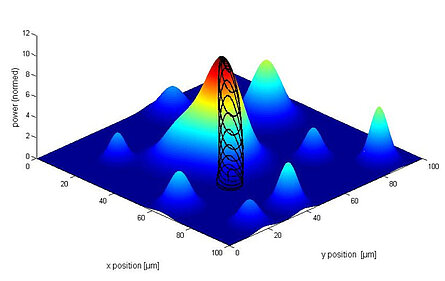

ピエゾスキャナーは、耐久性、ダイナミクス、そして精度が重要である、高速で継続的なスキャンのタスクに対応します。XYZの組み合わせ、または6軸のヘキサポッドを用いることで、より大きなトラベルレンジを実現できます。高性能コントローラーでは、複数の入出力を同時に最適化するファームウェアベースのルーチンを使用してすべての軸を制御します。統合されたルーチンにより、単軸アライメントから、複雑な多軸のファイバーアレイポジショニングまでを、最短時間で実行できます。ファーストライト検出、面スキャン、光強度の勾配検索に対応した効率的なアルゴリズムにより、処理時間0.6秒未満で産業向けの高いスループットを実現します。お客様の手でアプリケーションの最適化を行い、年中無休で最高のスループットを得ることも可能です。ユーザーフレンドリーなPIMikroMove®ソフトウェアにより、コントローラーの以下の機能すべてにアクセスできます。

高速マルチチャネルフォトニクスアライメントシステム

PIのFast Multi-Channel Photonics Alignment(FMPA)システムは、高度に特殊化されたデジタルモーションコントローラー(E-713)とハイブリッドアクティブアライメントメカニズムに基づいており、安定性、解像度、アライメント速度を犠牲にすることなく、必要な長い移動範囲を実現します。FMPAはE-713コントローラーのモジュラーファームウェアに実装されており、複数の自由度でマルチチャネルカップリングの高速かつ同時のアライメントとトラッキングを可能にします。最初の光検出、エリアスキャン、および勾配検索のための効率的なアルゴリズムにより、24時間365日の運用で最高のスループットが保証されます。

アライメント用ヘキサポッド

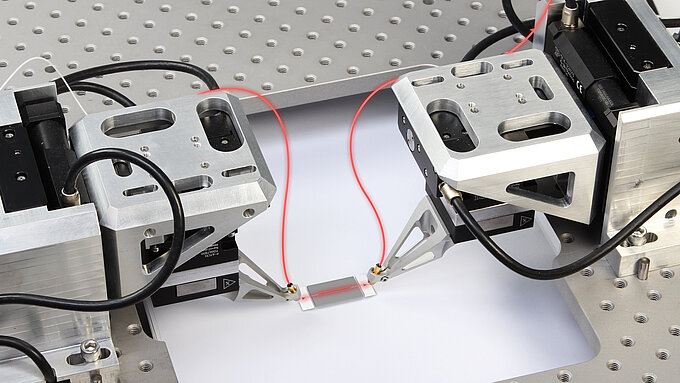

PIのヘキサポッドベースのフォトニクスアライメントシステムは、6自由度のモーションを提供します ヘキサポッドコントローラーには、最初の光を見つけてアライメントを最適化するコマンド用の多くの組み込みルーチンがあります。オプションのアナログ入力は、光パワーメーターで使用できます。ユーザーがプログラム可能なピボットポイントは大きな利点です。たとえば、ファイバーの先端、ビームのウエスト、SiPウェーハの表面など、任意の場所に設定できます。

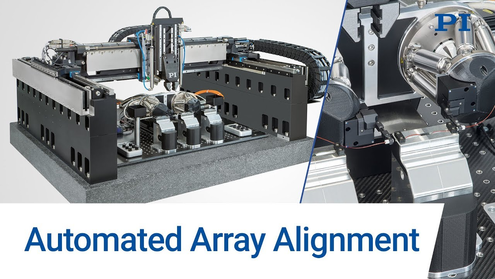

モジュラーアライメントエンジン

モジュラーアライメントエンジンは、リニアステージと回転用ゴニオメーターの組み合わせに基づいています。F-131の場合、ピエゾXYZスキャナーは、XYZモーター付きステージに取り付けられ、長距離移動します。ピエゾスキャナーは、超高速のスキャンと位置合わせ、または光学デバイスの出力特性を数分の1秒でマッピングできます。

ダウンロード

Practical Examples of Parallel Alignment Automation

Alignment for Optics and Silicon Photonics

Fast Multi-Channel Photonic System