真空環境用の精密位置決め装置の提供は、明確に定義された条件に従います。第1に、摩耗またはガス放出によるだけでなく、過剰な熱入力による真空チャンバーの粒子による汚染を回避する必要があります。さらに、設置スペースは通常限られています。PIは、真空技術とアプリケーション、および幅広い垂直型製造において長年の経験があります。したがって、PI は、真空アプリケーション の要件に正確に調整された標準および顧客固有の製品を提供できます。適切な駆動コンポーネント、材料の選択、設計、付属品、および適切な製造プロセスと品質管理によって。

真空環境へのポジショニングソリューション

PIは、真空アプリケーションに適したさまざまなモーションテクノロジーを提供しています。これには、強磁場および極低温環境で動作するピエゾアクチュエータ、移動範囲が1.5 mm未満でサブナノメートル精度のピエゾシステム、力、動力学、移動範囲に関してさまざまな設計のピエゾモーター、およびより広い移動範囲を可能にする特別に設計されたDCモーターまたはステッピングモーターによる古典的なモーター駆動が含まれます。

PIは開発された>>ピエゾアクチュエータをベースとした幅広い製品を提供しています。ピエゾアクチュエータは潤滑を必要とせず、摩耗しません。動作は>>ピエゾ効果に基づき、摩耗がありません。ピエゾ効果は電界に基づいているため、ピエゾアクチュエータは磁界を生成せず、磁場の影響も受けません。ピエゾ効果は、0ケルビンに近い最低温度でも存在します。さらに、圧電セラミックは高エネルギー放射の影響を受けません。>>PICMA®オールセラミック絶縁アクチュエータはポリマー絶縁を必要とせず、超高真空での使用に最適な条件を提供します。ガス放出がなく、150℃までの高い焼き出し温度です。

圧電アクチュエータの高い剛性により、高い力の発生とダイナミクスが可能になります。マイクロ秒の範囲での迅速な応答時間は、数百キロヘルツという高い共振周波数の結果です。ピエゾアクチュエータのトラベルレンジは、リニアアクチュエータの場合一般に数十から数百μmです。ベンディングアクチュエータでは、数ミリメートルのトラベルレンジを達成できます。ピエゾアクチュエータは、サブナノメートルの分解能を実現しています。

構成と制御に応じて、圧電セラミックアクチュエータは並進運動、有理運動(チップ/チルト) またはモータとして使用できます。駆動原理の選択は、それぞれのアプリケーションの必要な移動範囲、力、分解能、速度に依存します。ドライブのタイプの次には、適切な材料と追加のコンポーネントの選択が、圧電ベースの位置決めシステムを真空で使用するための決定的な要素です。このため、真空に適したハウジング、位置センサー、>>静電容量センサー などのガイドシステム、または>>フレクシャガイドが選択されています。更に、ピエゾモータは潤滑剤やグリース不要で動作します。

駆動原理に関係なく、すべての >>ピエゾモータ は真空で使用でき、特にミリメートル範囲の移動範囲が必要な場合に最適です。

| 真空度 | モーター | 測定システム | 材料 | ケーブルとコネクター | ガイドとスピンドル | ベント | ベークアウト温度 |

|---|---|---|---|---|---|---|---|

| 10-6hPa | グリースを塗ったモーター | 標準的な測定システム | アナダイズドアルミニウム部品;真ちゅうが許可されています。許可されたプラスチック | 2 m PTFE ケーブル 標準コネクター | 真空グリースとガイドとスピンドル | 一部はカニューレ付きネジ付き | ベークアウト温度:最大80℃ |

| 10-7hPa | HV モーター | HV測定システム | アルミニウム、ブランク;真ちゅうが許可されています。選択されたプラスチック | 2 m PIあるいはPTFE ケーブル UHVコネクター | 真空ガイド付きステンレス鋼製ガイドとスピンドル | カニューレ付きネジ付き | ベークアウト温度:最大80℃ |

| 10-9hPa | 特別UHVモーター 温度センサー | UHV測定システム | アルミニウム、ブランク;真鍮は許可されていません。 PEEKまたはポリイミド以外のプラスチックなし | 2 m PIケーブル UHVコネクター | 真空ガイド付きステンレス鋼製ガイドとスピンドル | カニューレ付きネジ付き | ベークアウト温度:最大120℃/150℃(測定システムなし) |

Tab. 1:電動ポジショナーの対応する真空クラスを達成するために取られたさまざまな対策

Positioning in High Vacuum (HV) and Ultrahigh Vacuum (UHV)

How Motorized Positioners Meet Requirements of Vacuum Applications

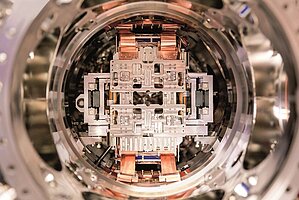

ヘキサポッドプラットフォームは、搭載物の6軸方向、つまり3つの直動軸と3つの回転軸に沿った高精度位置決め、および搭載物の位置調整のために使用されます。ヘキサポッドは>>パラレルキネマティック構造を備えています。つまり、可動プラットフォームは複数のアクチュエーターによって同時に作動します。パラレルキネマティックヘキサポッドでは、すべてのドライブが単一の移動プラットフォームで動作するため、スタックシステムで可能なものよりもはるかにコンパクトな設計になります。ヘキサポッドは高剛性 を備えているため、任意の向きで取り付けることができます。プラットフォームが1つだけ移動するため、スタックまたはネストされた位置決めシステムと比較すると、全体の移動質量が低くなり、慣性が低くなる ため、 すべての運動軸で同じダイナミクスが得られます。

ヘキサポッドは、設計に応じて、取り付け方向に関係なく、サブマイクロメータの精度で、数kgから最大数トンの荷重を任意の空間方向に配置できます。適切に設計されたヘキサポッドは、真空での使用に適しており、電気モーターまたは圧電ドライブおよび真空に適したセンサー技術を使用して、さまざまな真空クラスに適合させることができます。

必要な真空等級を判断するには、できる限り用途について理解する必要があります。たとえば、EUVリソグラフィ、マイクロエレクトロニクス回路の製造、またはSEM(走査型電子顕微鏡)を使用した材料分析では、圧力範囲だけでなく、真空チャンバー内の許容可能な残留材料にもさまざまな要求が課せられます。ゆえに アウトガス レートは別の関連する仕様です。多くの場合、HC(炭化水素)の分圧が決定的です。システム内の圧力(真空ポンプの容量とともに)を決定するため、ガス放出は低圧値の迅速な達成を妨げます。さらに、ガス放出化合物は、光学素子または他の敏感なデバイスの表面に堆積し、それらを覆い隠したり損傷したりする可能性があります。したがって、残留ガスにはHCがほとんどまたはまったく含まれておらず、亜鉛、鉛、カドミウムなどの蒸気圧の高い金属が含まれていてはなりません。

真空とは 容器内のガスの圧力があり、粒子数密度が外部よりも低い場合、またはガスの圧力が300 mbar未満、つまり大気圧の最低圧力よりも小さい場合のガスの状態です。地表への圧力{DIN28400}。[hPa]、[mbar]、[Torr]のいずれかで測定されます。さまざまなレベルの真空クラスが定義されています:ラフ、ファイン、ハイ、ウルトラハイ、およびエクストリームハイ(タブに表示)。2). PI社は、HVまたはUHV条件にすでに適している、選択された製品シリーズの標準製品を提供しています。さらに、ほとんどのPI製品は、真空での使用のために要求に応じて変更できます。PIが提供する製品は、10-9 hPaまでの大気圧を達成します。場合によっては、10〜12hPaに達することがあります

| 真空度 | Abbr. | hPa | mbar | Torr |

|---|---|---|---|---|

| ラフバキューム | RV | 300~1 | 300~1 | 225~0.75 |

| ファインバキューム | FV | <1 to 10-3 | <0.75 to 7.5 × 10-4 | <0.75 to 7.5 × 10-4 |

| 高真空 | HV | <10-3 to10-7 | <10-3 to 10-7 | <7.5 × 10-4 to 7.5 × 10-8 |

| 超高真空 | UHV | <10-7 to 10-12 | <10-7 to 10-12 | <7.5 × 10-8 to 7.5 × 10-13 |

| Extremly-high vacuum | XHV | <10-12 | <10-12 | <7.5 × 10-13 |

Tab. 2: 真空クラスの定義

真空アプリケーションの課題を克服する方法

ガス放出は、クリーンな高真空環境を作成および維持するための課題であるため、真空システムの設計と製造では、材料と処理の正しい選択が必須です。高(HV)または超高(UHV)真空用の製品を製造するには 材料の選択、設計、製造、 および試運転のプロセスを考慮する必要があります。

材料はガス放出しない可能性があり、より高い真空クラスに必要なベークアウト温度を克服するために耐熱性が必要です。ただし、必要な精度と高い位置分解能、および平坦性を維持する必要があります。

たとえば、一般的な電気および電子機器には、真空アプリケーションに適さないか、限られた範囲でしか適合しないコンポーネントが含まれています。これらには、ケーブル、モーター、スケーリングシステム、コネクタ、またはリミットスイッチが含まれます。PIは、これらすべてのコンポーネントに特定の製品機能を実装して、これらのコンポーネントからのガス放出を大幅に削減し、クリーンな真空環境を作成します。

したがって、真空位置決めシステムに使用される材料は アルミニウム合金、ステンレス鋼、チタン、または青銅です。高真空等級製品の表面は塗装せず電気研磨するなど、真空等級に合わせた表面処理を行っています。 高真空および超真空での用途では、専用の真空潤滑剤を使用しています。ご注文時に、ご要望に応じて潤滑剤を指定可能です。真空ケーブルの絶縁材にはまたは (テフロン)を用いていますが、ポリイミド(カプトン)またはも指定可能です。プラスチック類および接着剤の使用は可能な限り抑えています。

標準材料を 真空に適した材料に 置き換えることは、真空ステージ設計の厳格な 要件です。 もう1つの要件は、システムの表面の縮小と最小化です。

さらに、これらは真空中の仮想リークのように機能するため空気の混入を避けること が重要です。

このトラップされたボリューム内のガスは、真空チャンバーに接続するパスが狭いため、簡単に排出できません。これにより、必要な真空レベルに到達するのが遅れます。

トラップされたボリュームは通常、ベントされていない、またはベントが不十分なブラインドタップ穴によって引き起こされます。これらは、ネジの先端またはネジ頭の縁の下にあります。さらに、ポジショナーをベースプレートに取り付けるとき、またはサンプルをポジショナーに固定するときに覆われる穴は、多くの場合、仮想リークを引き起こします。ネジが原因で仮想リークが発生する場合は、たとえば、ベント付きネジの使用をお勧めします。

真空位置決めシステムの条件と取り扱い規則は、設計原則と同じくらい重要です。真空ステージの取り付けは、クリーンルーム環境で行われます。コンポーネントはすべて、超音波により洗浄されます。出荷は、粒子を含まない帯電防止パッケージに入れて行われます。真空ポジショナーを組み立てる前に、すべての純金属部品は超音波浴で 洗浄プロセスを受けます。電気および電子ユニットはワイプクリーニングされています。ベアリングやガイドなどの標準の潤滑部品は、脱脂、洗浄、および特殊な真空グリースで潤滑されています。超音波洗浄されたコンポーネントは、気候チャンバー内で乾燥されます。

ステージの組み立て は >>クリーンルーム またはフローボックスで行われます。組み立て後、ステージはクリーンな環境でのパフォーマンステストに合格する必要があります。真空テストは、ステージのタイプごとに、および製品に真空クリティカルな変更が加えられたときに実行されます。組み立て後、システムは汚れ、空気、湿度から保護された 真空シールされたバッグに詰められます。最初に、ステージは気候チャンバーでベーキングプロセスを経ます。内側の真空バッグに梱包して密封した後、ステージを2番目の外側の真空バッグに入れ、完全に真空シールします。

真空に適した製品は、 PIで標準テストを受けます。さらに、カスタマイズされたテストは、個々の真空アプリケーション用に注文できます。PIには、ベークアウトと残留ガス分析用に容量の異なるいくつかの真空チャンバー があります。

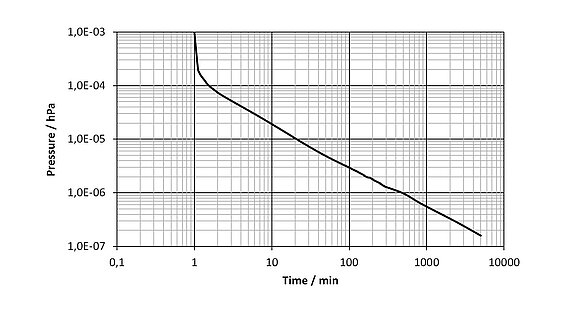

単一コンポーネントのテストまたは小さなステージのテストには、約10リットルの容量のチャンバーを使用できます。小さな真空チャンバーには、400 l / s(N2)ターボ分子ポンプと連続圧力検知用の圧力センサーで構成され〜10hPa未満の圧力に到達できることを意味します。暖房設備では、最大200℃のベークアウト温度が可能です。

容量260lの大型チャンバーは、長さ800 mmまでの大型ステージ、ヘキサポッド、および多軸システム用に設計されています。700 l / s(N2)ターボ分子ポンプと圧力センサーを備えたポンプスタンドにより、10〜9hPaまでのテストが可能です。統合された暖房システムを使用すると、最大150℃のベークアウト温度が可能です。

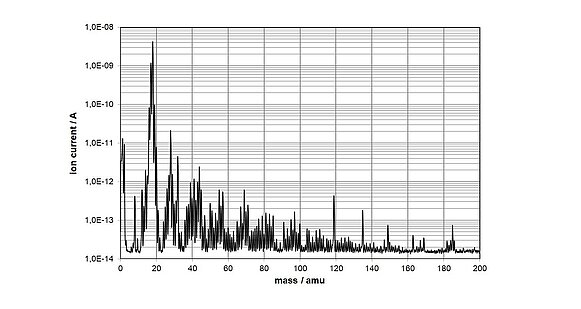

ステージでの真空動作テスト では、さまざまなフィードスルーを備えたモーター電流、リニアエンコーダ、リミットスイッチ、温度センサーなどにさまざまなサイズのフランジを使用できます。干渉測定が必要な場合、 または プロセスの目視観察が必要な場合は、両方のチャンバーに検査ウィンドウを装備できます。四重極質量分析計は、1amuから200amuのリアルタイムRGA(残留ガス分析)に使用でき、両方のチャンバーに取り付けることができます。

PIは、真空チャンバー内の真空圧測定とRGA(残留ガス分析) によって真空製品を分類および検証します。どの真空レベルに到達する必要があるかに応じて、チャンバーとステージはそれに応じて焼き付けられます。